Exploring helmet manufacturing reveals a meticulous process, emphasising safety and quality from raw materials to stringent testing – a behind-the-scenes look at the craftsmanship behind this vital protective gear.

Compiling Necessary Supplies:

The helmet production process begins with the acquisition of raw materials. Key components include foam for interior padding, polycarbonate plastic for the outer shell, and durable materials like nylon for straps and buckles. Suppliers provide these materials, which are then shipped to the manufacturing plant.

Development And Design:

Engineers and designers collaborate to create a prototype, considering crucial factors such as weight, fit, and ventilation. User-specific needs are also taken into account, be it for athletes, construction workers, or other groups.

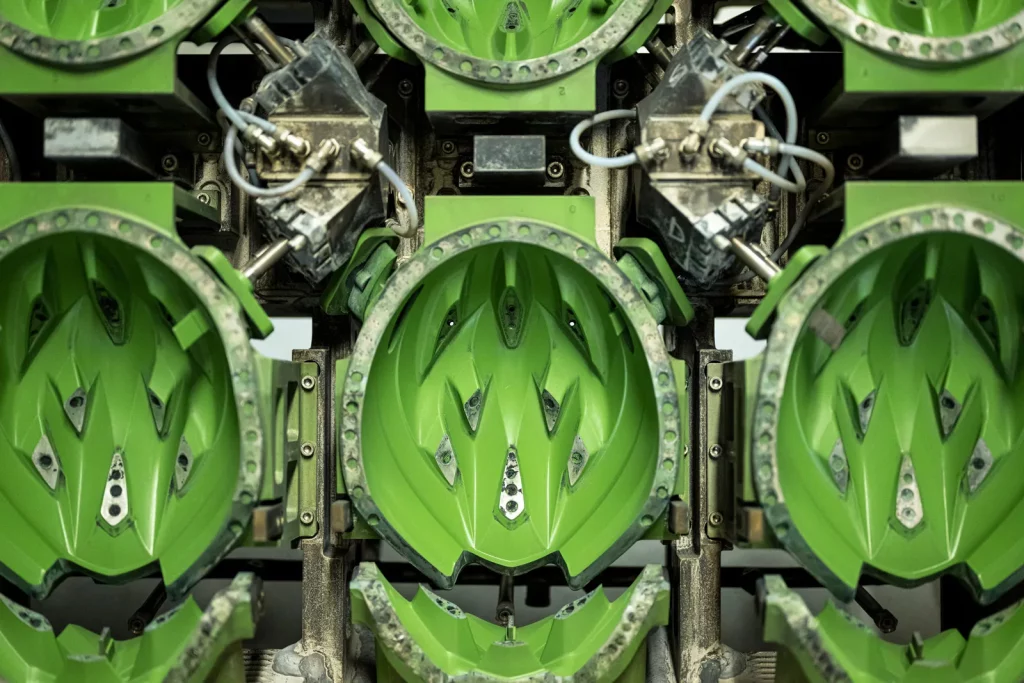

Creating Moulds And Forms:

Upon finalising the design, raw materials undergo moulding and shaping using techniques like injection moulding. The heated materials are injected into moulds that resemble the intended helmet design. After cooling, the components are assembled to form the complete helmet.

Putting The Helmet Together:

Assembling involves securing the straps and buckles, attaching the outer shell to the inner padding, and incorporating additional features like ventilation holes or reflectors.

Quality Assurance And Testing:

Helmets undergo rigorous testing to ensure they meet safety standards before reaching customers. Impact testing simulates collisions, evaluating performance. Additional tests assess fit and ventilation. Only after passing all tests is a helmet deemed ready for sale.

Helmet Standards:

Safety standards are vital for helmet effectiveness. The Bureau of Indian Standards, formerly the Indian Standard Institute (ISI), creates guidelines, while international organisations like the US Department of Transportation (DOT), SNELL, ECE, and SHARP provide safety ratings. These standards evaluate impact and penetration resistance, retention system strength, and other relevant factors. Manufacturers must subject their products to these tests to ensure safety and functionality.

Safety:

The paramount goal in helmet production is safety. The multi-step process and adherence to stringent standards have significantly reduced the risk of head injuries and fatalities. Purchasers are urged to prioritise safety certifications from recognised bodies when selecting a helmet. The dedication to detail in manufacturing ensures that this essential protective gear offers reliable protection, emphasising the worth of the effort invested in its production.

In concluding our journey through the helmet manufacturing process, it’s evident that safety stands as the paramount concern. The rigorous adherence to standards and attention to detail have significantly reduced head injuries. As riders contemplate safeguarding themselves on the road, investing in a well-crafted helmet and considering the broader spectrum of protection is crucial. Beyond the manufacturing process, securing a robust two-wheeler insurance policy is integral to comprehensive road safety practices.

Securing a two-wheeler with third-party insurance provides essential financial protection for riders in the event of liabilities arising from accidents involving their vehicle. Always ensure you carry out the process of two-wheeler insurance renewal on time for uninterrupted coverage. Claims are subject to terms and conditions set forth under the motor insurance policy. *

As helmets shield individuals physically, a firm two wheeler insurance policy provides financial protection, completing every rider’s safety circle.

*Standard T&C Apply

Disclaimer: The content on this page is generic and shared only for informational and explanatory purposes. It is based on several secondary sources on the internet and is subject to changes. Please consult an expert before making any related decisions.

Insurance is the subject matter of solicitation. For more details on benefits, exclusions, limitations, terms, and conditions, please read the sales brochure/policy wording carefully before concluding a sale.

More Stories

Why Love and Travel Belong in Every Great Story

Why Professional Landscape Drainage Assessment is Worth Your Investment

OUSM Power Adapter Manufacturer Supply High Quality Power Solution